New production line for Akoestikon systems has a new home

The sound absorbing systems by our brand Akoestikon, which are used in construction, have recently become part of our new production line in Gorinchem, where Merford is based. Peter Fernig, Manager Operations Merford Acoustic Materials, tells us more about Akoestikon and the characteristics of the new production line. For example, the new production line can quickly switch from cold glue to hotmelt for an instant gluing of the plates. “Previously, we had to wait 24 hours to do this but thanks to hotmelt, the systems can be loaded onto the pallet almost immediately,” Fernig explains.

Safety, ergonomics and new technologies

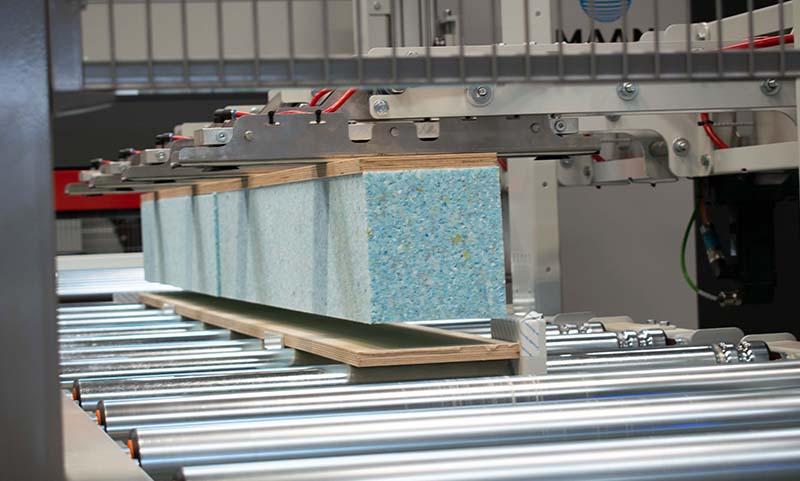

Fernig talks about the new production line with great pride: “When it comes to safety and ergonomics, we have made several improvements. In addition, we have also implemented new techniques in the process. The most important novelty, which required a great deal of research, is the use of hotmelt instead of cold glue to attach the foam to the plates. Previously, the sandwich board panels had to dry under a stamp for 24 hours in order to guarantee a proper adhesion. Now, this is no longer the case. Hotmelt binds as soon as the glue cools down. At the same time, the glue is waterproof and high-temperature resistant. The new glue could potentially also be used for other materials such as plastic or even steel. This could be interesting for future product developments.”

Peter Fernig (Merford): “Construction acoustics is truly a niche industry. And within this industry, Akoestikon has made a name for itself. Our customers are looking for a complete solution and our specialist advice is an important part of that.”

A niche industry

Akoestikon's sound-insulating systems are suitable for a pre- or post-installation insulation of buildings to prevent both airborne and impact noise. The systems can be used for every conceivable application in the hidden building components of roofs, ceilings, walls and floors, and in both new constructions and renovation projects. The sound-insulating systems are easy to install and, without any exception, provide great noise reduction. Akoestiplex profiles or Akoestiregels are built up of absorbent flock foam and sheet material such as plywood. When applied correctly, the systems will mute airborne and impact noise in an optimal way. Fernig adds: “Construction acoustics is truly a niche industry. And within this industry, Akoestikon has made a name for itself. Our customers are looking for a complete solution and our specialist advice is an important part of that.”

Gorinchem: flexible and modern production

The old production line dated back to the 1990s and was therefore becoming a bit too vintage. In order to make our production process more flexible and to allow for more product development opportunities in the future, a makeover was in order. Merford felt a strong urge to accommodate the Akoestikon production line in Gorinchem as this is where almost all of Merford's activities take place and where the offices are located. In October of last year, the construction of the racks for the new Akoestikon warehouse began next to where the first contours of the new machines soon became visible. In early January of this year, all the components of the new production line were in place. After a few test days in mid-January, the new production line was open for business towards the end of the month.