Merford develops anechoic chamber for the new construction of the Netherlands Aerospace Centre

We’re proud to be part of the Merford family, and here we take a look at a recent project delivered by Merford Noise Control.

Netherland aerospace centre: NLR

'Netherlands Aerospace Centre' can be read above the entrance of the brand new building in Noordoostpolder, the Nethlerands.

This is where NLR, the Netherlands Aerospace Centre, resides. Its predecessor was founded in 1919, which means that the royal institute has existed for more than a hundred years. Originally it focused on increasing the security of military aviation, but civil aviation was soon added to that.

To this day, the foundation promotes the safety, efficiency and sustainability of aviation and space travel for and with a wide variety of parties from the sector. It sees itself as the connecting link between science, industry and government.

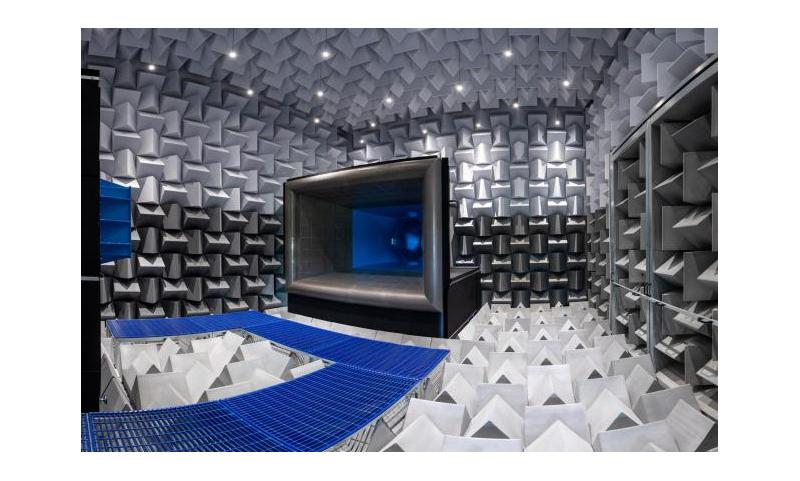

In its new building in Marknesse, research is being conducted into aircraft noise, among other things. In a specially designed hall is an anechoic chamber that is used to analyze and locate sound sources. The acoustic solutions are designed and supplied by Merford, who worked closely with the NLR team.

Anechoic chamber

Wind tunnel tests are carried out in one of the halls in the building. In the space there are two wind circulation circuits, a 'flow duct facility' and 'acoustic wind tunnel', which are used for noise tests in which a realistic setting is created when it comes to air speed and flow.

One of the circuits carries the air at a speed of up to 110 meters per second through a 432 m3 anechoic chamber, where rotor blades and 'engine casings' can be tested, for example.

This room is designed in such a way that sound reflections are kept to a minimum, a requirement for reliable measurement results in many noise studies.

Anechoic chambers are also called dead chambers, because all sound is almost immediately cut off, meaning there are no echoes. This enables accurate acoustic measurements to be undertaken for specialist acoustic research.

Acoustic design

The Anechoic chamber is constructed from hundreds of wedges of the sound-absorbing melamine foam Flamex. These pyramid-shaped objects are attached to the walls and ceiling with an innovative framing support system. They are separate on the floor, so that the room can be easily adapted if a new test setup is placed in the room.

We can also provide a wide range of acoustic panel and enclosure systems to further isolate the chamber from background noise.

Joost Hakkaart, Head of Vertical Flight and Aeroacoustics at NLR, is satisfied with the result and the road towards it: “The collaboration with Merford for our new aero-acoustic wind tunnels started in 2016, when we were still working on the investment application for the new facility. From the start, Merford has been involved in the realization of a technically sound and cost-effective solution.

The work involved not only the eye-catching anechoic room, but also splitter dampers for both wind tunnels. We are most impressed by the limited installation time, which was mainly due to the good engineering. During the realization, a very pleasant collaboration arose, as a result of which recent acoustic improvements were also awarded to Merford. ”

Experts in acoustic testing facilities

This is not the first time Merford have delivered a world class anechoic chamber, at the beginning of 2016, Merford designed and installed a hemi-anechoic chamber for the University of Ghent.

Such rooms are used for acoustic research, in which no reverberation may occur, for example undertaking sound power measurements for declaration purposes.

The anechoic chamber for the University of Ghent has an exception low cut-off frequency of 63 Hz. Merford provided the complete solution, from design to full assembly.

Efficient absorption measurement

In collaboration with the University of Ghent, Merford went in search of the best system and material. The walls and ceiling are covered with Flamex elements in a wedge shape. The most effective measuring field can be achieved thanks to the careful selection of acoustic materials and design used. Depending on the nature of the measurement, the floor can also be covered with plates provided with the absorbent elements, to covert to a full anechoic chamber.

The room has double doors, enable large test objects to be measured. The door on the inside of the room, also provided with absorption material, can be moved in its entirety for ease of access.

Optimal sound analysis using Merford's test and measurement cells

Test and measurement cells provide an important added value in various applications. There is a distinction between test cells and measurement cells.

Test cells are chambers where power output tests are conducted with vehicles such as motorcycles and cars. Here it is important that the associated noise pollution stays within the chamber, so that personnel does not run the risk of incurring hearing damage.

Measuring cells are used to conduct measurements that may not be influenced by sound from the external surroundings, such as acoustic transmission and reception rooms and rooms for conducting audiometric (hearing) tests.

Applications of this nature require an elaborate approach. In many cases, the chamber must be equipped with specific test or measuring equipment, a gas exhaust system and ventilation facilities.

The test cells are always equipped with (forced) ventilation to remove the heat created within the test cell. The necessary air flow is determined by Merford in conjunction with the customer based on the capacity of the test object.

The ventilation has heavy acoustic dampers that have the same insulation values as the panels used. These sound dampers are of a high quality and are cleanable. The acoustic ventilation system can also be used to simulate driving winds at high speeds. Ventilation flows of up to approx. 200,000 m3/hour are possible.

Measurement cells for pure results

Our measurement cells can be fitted with a silent ventilation system, optionally in combination with filters and (fire) valves. Merford’s measurement and test cells can be constructed using individual panels.

This makes it possible to disassemble the cells fully or in part to be rebuilt in another location. Furthermore, hatches, doors, or roofs and walls that slide fully open can be installed.

Experienced partner

Merford has 35 years of experience with the application of test cells and measurement cells in various industrial sectors, as a result of which we understand your specific problem perfectly. Merford always provides you with a ready-for-use solution. We provide noise control guarantees so that you can be sure that the test or measurement cell meets your specified requirements.