Want to know more? Ask your question!

In the previous article from this series, we described the concept phase of the NoiseTrap® Blox. This time, we focus on the next step in the development process: real-life testing of the accuracy of the computer simulations. We made full-size prototypes for experimentation. With metamaterials the emphasis is on the shape of the material, so we used 3D printed samples. Sonobex has eight 3D printers to enable rapid prototyping. The printers were used to build the complex internal shapes with which the tests are carried out.

The acoustic tests were carried out in the Merford sound laboratory in Gorinchem, which consists of two reverberation chambers. The samples were used as a partition between the two reverberation chambers. Speakers in the source room emit white noise (all audible frequencies of equal amplitude). The sound levels are measured in the reception room. The noise reduction that the prototype achieves is the difference between the noise levels in the two rooms. The standard requires a representative size setup to be used for the survey. In the case of NoiseTrap® Blox, it was a matrix of three samples in height and three in length. It measures approximately 750 by 750 mm; a common size for grilles in industrial machine enclosures.

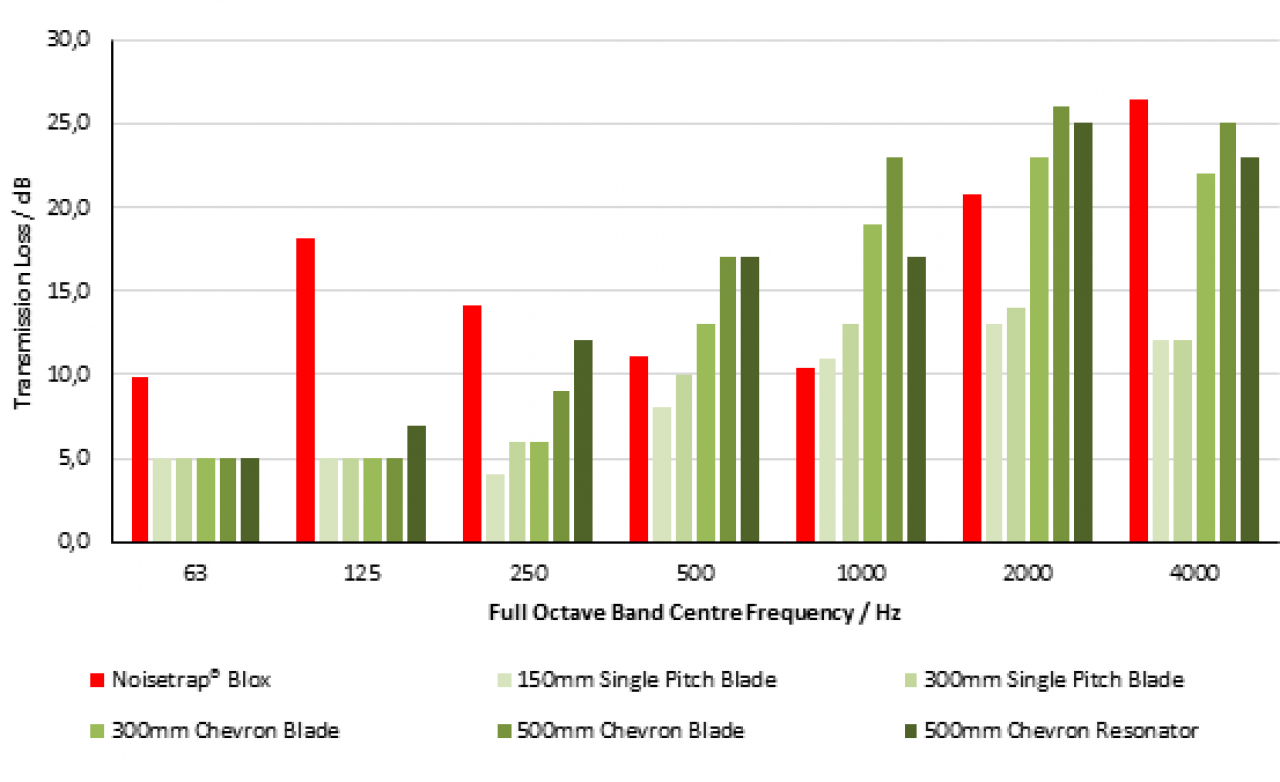

The first tests for the NoiseTrap® Blox immediately showed impressive results. The simulations turned out to be accurate and we achieved exceptional performance at low frequencies. The graph compares the result of NoiseTrap® Blox with other noise-reducing grilles. The graph shows that the NoiseTrap Blox achieves 18 dB transmission loss in the 125 Hz band. This is many times larger than soundproof grilles of a comparable thickness.

In order to be able to compare properly, various conventional grid designs were also tested during the laboratory study. Measuring equipment and environment were thus constant, which makes the measurement results reliable. The graph shows that the performance is also impressive at high frequencies. This is due to the use of an absorbent foam lining on the inside of the air channel. Absorbents are good at damping high-frequency noise, while the metamaterial structure tackles low-frequency noise.

The results of the laboratory tests have proven the success of the NoiseTrap® Blox concept. The goal of the next phase was to translate the prototype into a product that could be mass-produced at a competitive price. You can read all about it in the next and last part of this series.