Considered factors

Enhanced analysis of the following factors are considered as part of the noise audit process.

Types of noise

Noise levels and temporal patterns

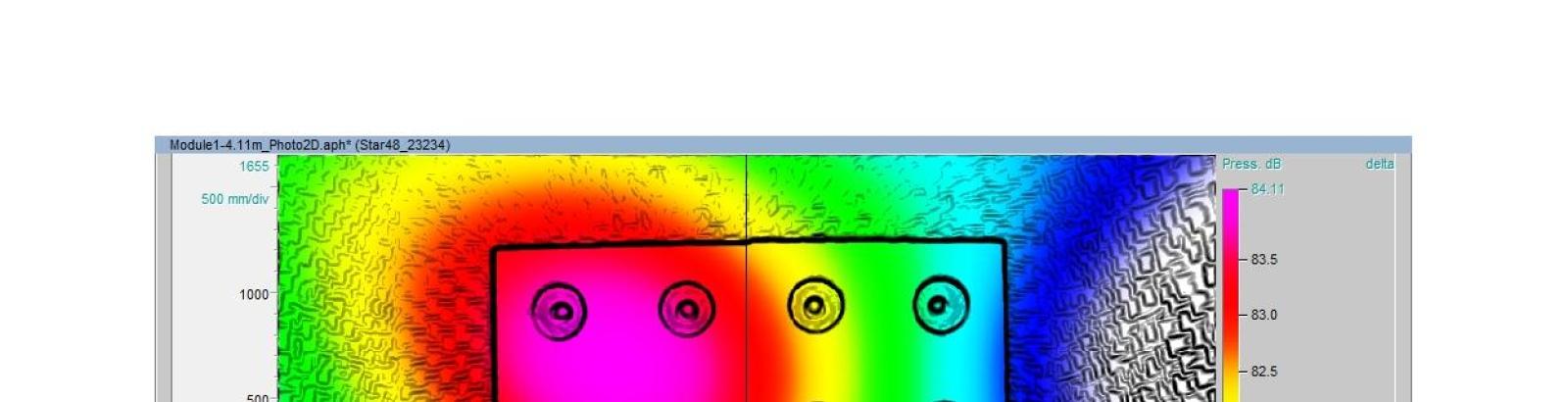

Frequency distribution

Noise sources (location, power, directivity)

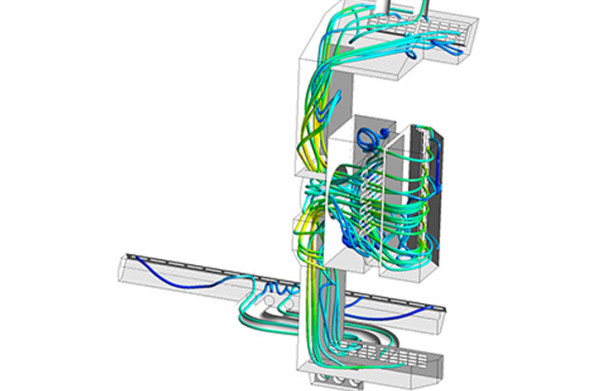

Noise propagation pathways, through air or structure

Noise rank order – in terms of contributions to excessive noise.

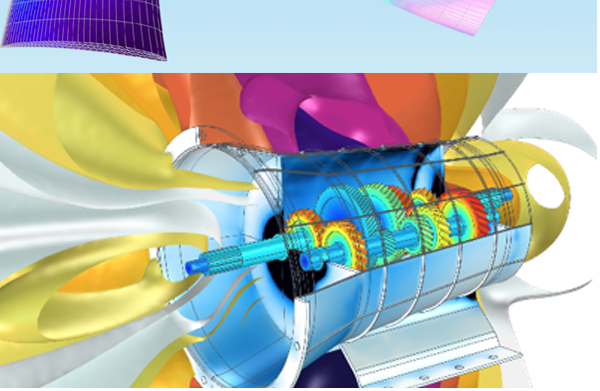

For example such sources may include the noise directly radiated by a motor when under load, structure-borne noise due to vibration transmitted from the same motor to various connected structures, the blade passage tonal noise associated with a cooling fan, noise due to gear mesh, noise due to airflow etc.

Following identification of the common noise sources, the next step is to determine the noise produced by each individual source. The most straightforward way to do this is to operate a source by itself while maintaining representative speed, load, temperature etc.

Sonobex is experienced in designing and constructing experimental test rig setups to ensure that operation is as close to real life as possible, ensuring accurate representation of the appliances "normal" sound field.